Understanding the Strength Behind Disposable Hygiene Adhesive Testing

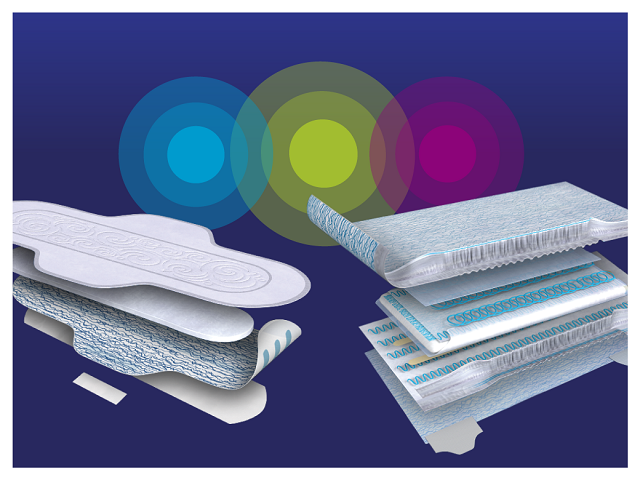

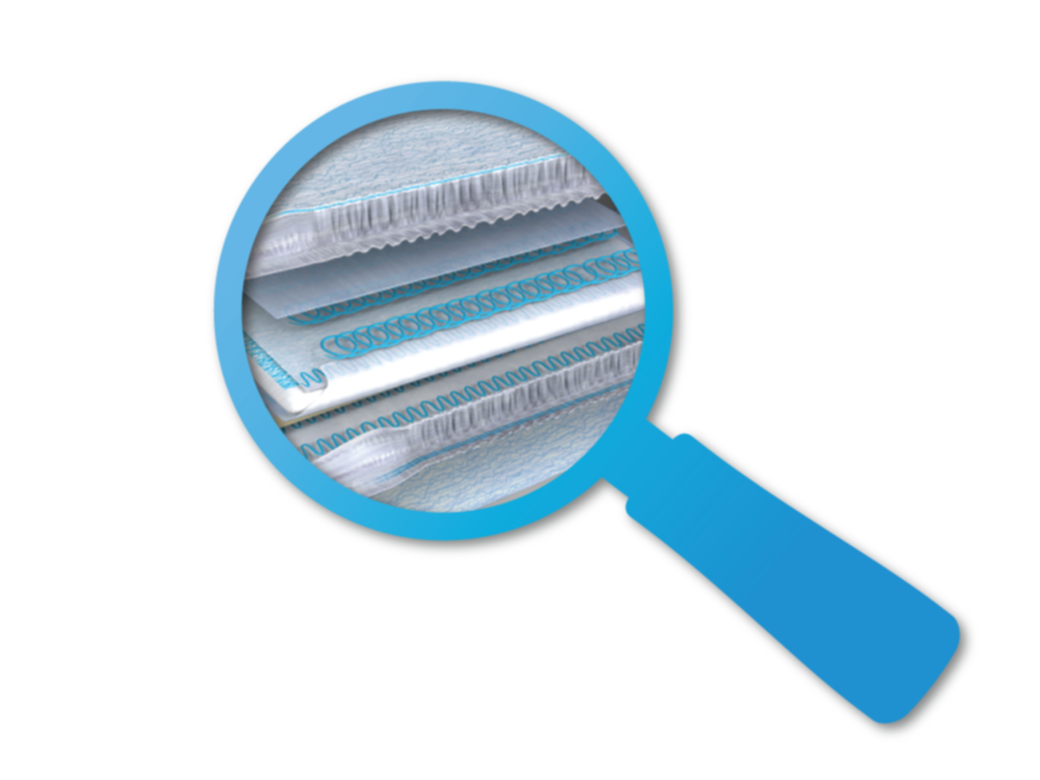

Disposable hygiene adhesives perform a wide variety of tasks. They are used for constructing a diaper core, attaching elastic strands for pant diapers, securing feminine pads to undergarments, and much more. Reliable performance is critical with every use.

This makes choosing the right adhesive—or combination of adhesives—for the various applications an important step in ensuring product quality and keeping consumers satisfied. To do so, it helps to have an understanding of the performance testing for each of the adhesive’s relevant attributes:

Adhesive Add-On

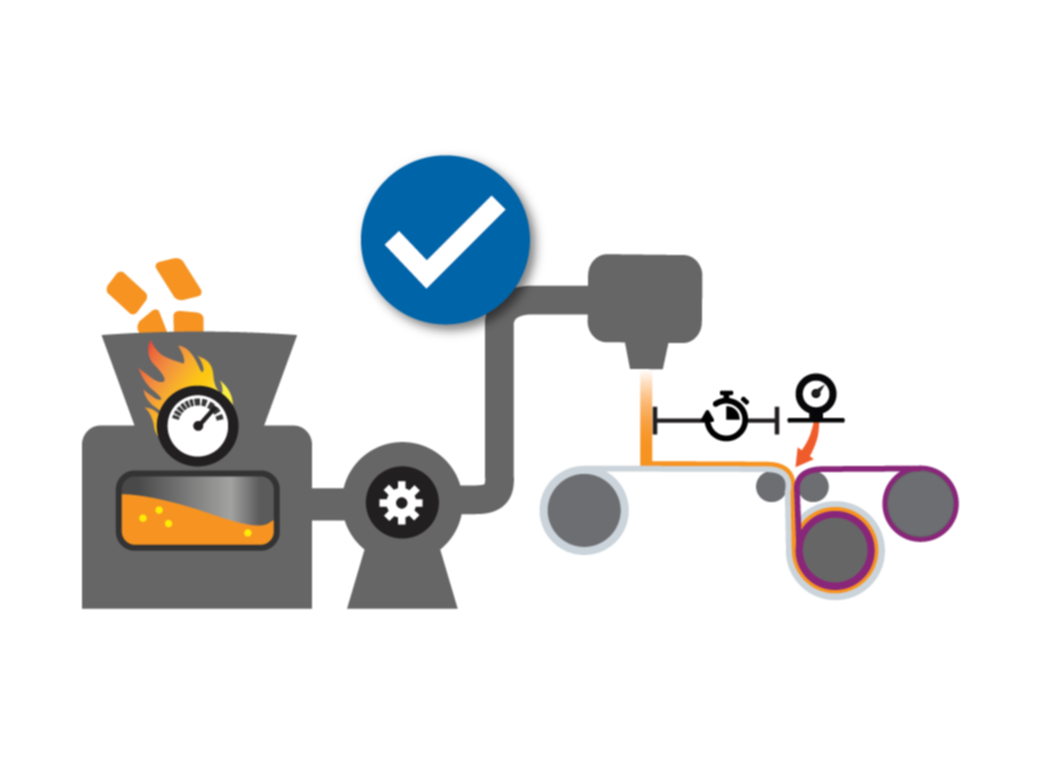

Adhesive add-on testing is used to ensure that the target amount of adhesive is applied. The cup test can be used during production; the solvent test measures the amount of adhesive in the finished product.

Creep resistance testing helps ensure elastic adhesives can prevent slippage while the elastic stretches and retracts.

Several qualities of the hot melt wetness indicator should be tested to ensure proper performance. These include fast and clear colour change after insult, resistance to humidity, reliable processability, and thermal stability.

Peel

Peel strength testing identifies both the force needed to break bonds, such as those keeping the core sealed and ear tabs attached, as well as determining the failure mode.

The static shear hang test evaluates an adhesive’s resistance to pulling free of substrates.

The ring and ball test determines a single temperature within a hot melt adhesive’s softening range, which reflects the adhesive’s “set point”—the point at which it stops flowing.

In addition, finished products can be tested to help predict consumer experience:

Testing for odour, which can include chemical analysis, human odour panels, or a combination of the two, before a disposable hygiene article is in use can help provide insight on whether or not users find the product pleasant or unpleasant.

Conditioned Core Cracking Test, created by Bostik, evaluates a dry and wet core’s ability to resist cracking, which can lead to sagging, slower absorption rates, and leakage.

Softness

Testing for softness can include physical analysis, human sensory panels, or a combination of the two. Cultural preferences can play a large role in the perception of softness.

Staybility™ Testing, also created by Bostik, helps ensure a feminine pad stays in place on an undergarment to prevent leakage that may occur as a result of movement during daily life.

As you evaluate the performance of your disposable hygiene products, keep in mind that your supplier should be able to provide you with performance testing results for their adhesives. Additionally, they should be able to provide insights on how to choose the right adhesive(s) for your various product and application needs.

Learn more about adhesives used in disposable hygiene products in Bostik’s Adhesives 101.