Resist Creep and Shear With the Right Disposable Hygiene Elastic Adhesive

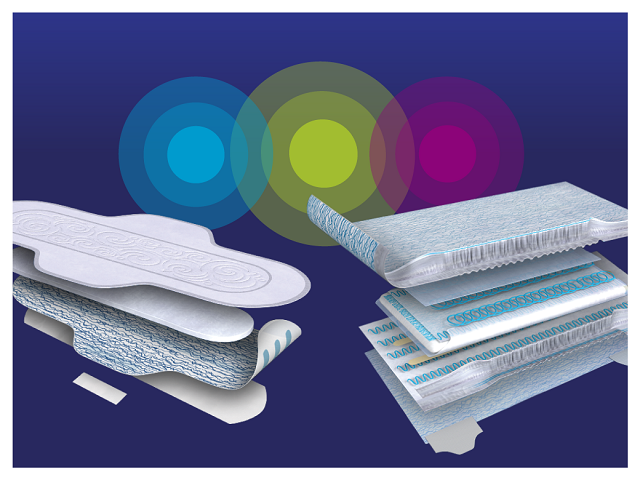

From traditional diaper designs to pullups for baby care and adult incontinence, disposable hygiene products often require robust adhesives for high-stress applications. In particular, designs utilising elastic strands rely on powerful creep performance and shear strength to function at their best.

Why are creep performance and shear strength important?

Consumers want a comfortable stretch in the waistband and leg cuffs that ease back in to place when tugged or pulled. Elastic strands at the leg cuffs also assist in keeping liquids inside to protect against leakage. Creep performance and shear strength are important to an adhesive meeting these performance expectations.

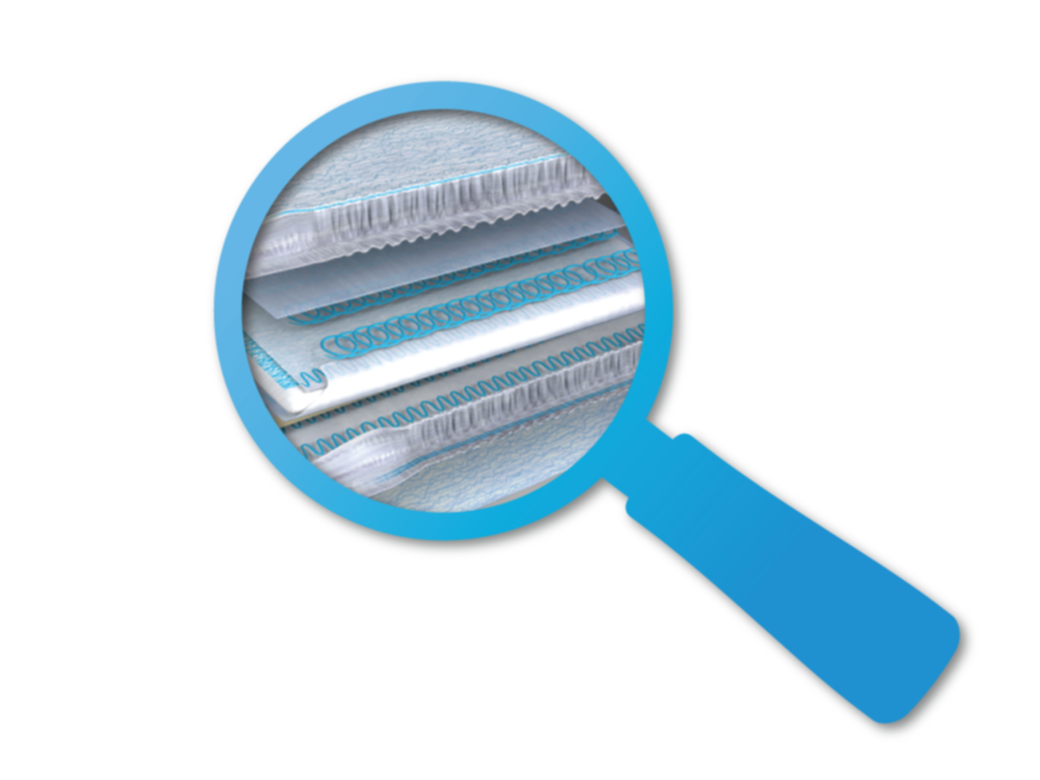

Creep is associated with elastics slipping from where they were bonded down and becoming loose. Reducing slippage allows the elastics to perform effectively for a longer period of time. Creep testing typically measures the distance an adhesive allows a strand to move when stretched under specific conditions.

Shear strength, on the other hand, measures an adhesive’s ability to resist breaking under the pull of lateral forces. Shear strength is important for high-stress bonding applications such as attaching ear tabs, holding them firmly in place. In the case of disposable hygiene products used in hospital, nursing home, and in-home nursing settings, caregivers may use the side panels of a diaper to help lift and move patients. In this case, a shear failure could render the product unusable or possibly result in injury.

To ensure strong shear performance, the static shear hang test is a common choice among disposable hygiene adhesive suppliers.

The impact of line parameters on creep and shear strength

Achieving optimal results also requires that an adhesive is optimised for the production line on which it is used. Factors such as temperature, add-on, and application type can all impact an adhesive’s ability to bond and set up correctly. If conditions fluctuate or are outside of recommended values, the adhesive will not perform up to its full potential. Maintaining proper parameters also helps ensure accurate application patterns and product aesthetics, as well as minimise product blocking.

When evaluating any adhesive, choose a partner that understands your performance and production needs and can help determine how well its recommended parameters fit with your production lines and substrates. Also ask what other services they can provide. The choices you make today can have a significant impact on product performance, consumer confidence and sales and profitability for years to come.

Keep Reading

Learn how the right adhesive can positively impact operations when you read Why Peel and Shear Can Make or Break Your Operation.